|

|

|

Tel: +86 13924846630 |

Why more beer bottles are covered in UV-curable inks |

| Author : DENISE BREARD Date : 10/3/2013 1:02:00 AM |

According to the Glass Packaging Institute, Alexandria, Va., energy costs drop about 2 to 3% for every 10% cullet used compared to making new glass from only raw materials. Cullet (broken or refuse glass) is used in the process of remelting glass. While bottles covered in traditional fired-ceramic labels can be recycled into cullet, bottles covered in UV-curable inks can be converted more efficiently. Denise Breard, a member of the Academy of Screen Printing Technology, Fairfax, Va., shared with us the advantages of using UV-curable inks.

What are the advantages of using UV inks instead of traditional fired-ceramic labels? Fired-ceramic colors become part of the glass permanently. Glass cullet with ceramic color cannot be recycled into clear flint glass, and must be “down-cycled” into colored glass. UV inks do not contaminate the cullet and can be converted into clear flint glass. In addition, UV inks require less energy. Ceramic or glass-frit inks must be fired in a high-temperature lehr reaching up to 1,200°F for as long as 30 min. Under exposure to high intensity UV light, UV-curable inks cure in a fraction of a second.

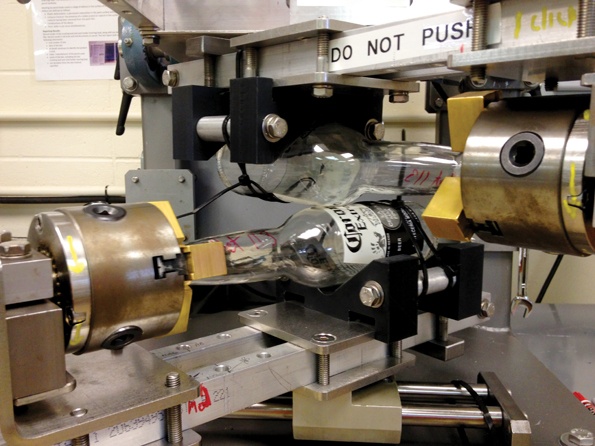

UV inks and coatings can also be more eco-friendly. Specifically, UV inks contain low to no volatile organic compounds (VOCs). Concern over heavy metal pigments is shifting the market from ceramic labels to UV-curable inks. Bright reds, yellows, and greens are traditionally produced with heavy metal pigments. With UV inks, these colors and many more can be easily created with organic pigments. Inks and coatings are also effective on polyethylene terephthalate (PET or polyester) bottles that are commonly used for soft drinks and other beverages. And the UV process uses less ink to print images with good print definition because it employs screens having finer mesh counts. How are the bottles decorated? UV-curable inks and coatings can be applied and cured with different methods. The result is a variety of decorative looks. Screen printing is a method where the glass is prepared for decoration with flame and wash. The bottles are then screen printed and the ink is cured under UV light. The finished bottle has texture on areas where the screen can reach the bottle. The electrostatic method is another application technique and is interesting because glass is an insulator. Here, a charged ink is directly sprayed onto the bottle, and then the coating is quickly cured by exposure to UV light from electrode-free lamps. Electrostatic spraying is more efficient than traditional spraying and screen printing because it coats the back of the bottle as well as the front with only one nozzle. The entire bottle can be coated, or the lip (finish) can be left unmarked. This method is a candidate for clear flint glass bottles because it economically coats with almost any color. Variable textures are also possible with UV-curable coatings. The inks themselves create different looks. Transparent or opaque colors can be applied to create special effects that are not possible with fired-ceramic decoration. Examples of these special effects include fluorescent (day glow), phosphorescent (glow in the dark), metallic, pearlescent, thermochromic (change color when hot or cold), photochromic (change color in sunlight), glitter, scented, prismatic, or flip/flop color shift (color changes with viewing angle). What’s new about the technology? Water-resistant inks for plastics, as seen on shampoo bottles, have been available for many years. Recent advances in resin technology make inks water resistant and suitable for glass bottles. Before these advances, UV inks for glass lacked features such as full adhesion, abrasion resistance, and resistance to water and ice which is also an issue with paper labels.

Now, UV-curable ink and coating systems create robust decorations that will resist conditions on high-speed filling lines as well as water, ice, cleaning chemicals, solvents, and product contents. For example, a beer bottle decorated with UV-curable ink can now survive the filling line and remain stuck to the bottle when placed in an ice chest with other bottles, cans, and water from melting ice. What came first, the process or the inks? The polymer system came first, then inks and coatings were developed at a basic level. The formulas and raw materials were optimized while the treatment and handling equipment were designed and manufactured. What industries use UV inks? Many craft beer, wine, and spirit bottles are decorated with UV-curable inks. We have been working with several organizations (breweries, wineries, distilleries) on bottles readily available in retail stores. Large-scale multinational brewers are less likely to use coated or direct screen-printed bottles because of the speeds and quantities involved, but these decoration methods are candidates for those who want a higher end or custom special look for their bottles. What are the important properties to consider when choosing an ink? The inks and resin system should yield good adhesion to glass and PET. Resins can be used in radiation curing with UV and electron beam (EB). For UV curing, low-migration photoinitiators can be used so the curing process doesn’t affect organoleptic (taste and odor) properties of food and beverage products in the bottles. Inks should not contain solvents or VOCs, heavy metals, or Bisphenol-A (BPA).

How are bottles with inks disposed? Glass bottles are always recyclable, and energy consumption drops with rising percentages of cullet in the mix with new glass. UV inks burn off during the recycling process, so all glass returns to its original color, most often clear flint glass. What’s in the future for the technology? The technology was once limited to the manufacturers who developed the system. Today, there is commercialization of equipment and process technology along with inks and coatings. The technology will probably start popping up in other manufacturing facilities so companies can offer one-stop decoration and packaging. What was the hardest challenge in developing the technology? We’ve focused on solving challenges in several areas, from handling and treatment of the glass, to optimization of the curing process, to developing intensely pigmented inks that show strong color even on amber bottles. There are also challenges in measuring film weight or coating thickness, speeding the production process toward 400 bottles/minute, and troubleshooting brown bottles which naturally block UV. |

Spray Coating Line

Spray Coating Line