|

|

|||||||||||||||||||||||||||||||||||||||||||

|

Tel: +86 13924846630 |

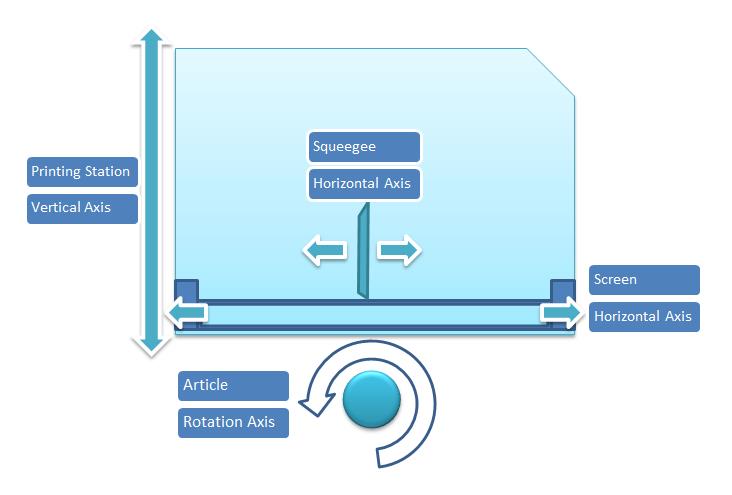

CNC Screen Printing Machine for Large Bottles (7 Colors Thermoplastic Ink) |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Machine : CNC Screen Printing Machine for Large Bottles (7 Colors Thermoplastic Ink) | |||||||||||||||||||||||||

| Machine Model : R 307 | |||||||||||||||||||||||||

| Details : | |||||||||||||||||||||||||

Highest color-to-color registration accuracy All 4 axes (Squeegee, Screen, Article Rotation & Article Elevation) are controlled and driven by high accuracy servos. Capable of printing on almost all bottle shapes R 3 series is design for printing on: Cylindrical, Oval, Square, Flat and other bottle shapes Custom Design is possible R 3 series can be fully custom designed to meet your need. High rigidity machine structure Ideally suitable for heavy and large diameter glass bottle printing Matured technology and machine designReliable machine performance with low maintenance cost High output of 55 pcs/min.

|

|||||||||||||||||||||||||

|

[Previous : RUV 3 Series] [Next : LUV 202 (Optical)] | ||||||||||||||||||||||||

| Related Products : |

Spray Coating Line

Spray Coating Line